08.0 6.2007 — In today’s volatile market, manufacturers are waging war against the rising costs of raw materials, packaging, freight and production overhead. These costs have an impact on the price of the materials used in a quality low voltage installation. To make matters worse, residential construction, a savior for many installers, has refused to be the leader it once was. 6.2007 — In today’s volatile market, manufacturers are waging war against the rising costs of raw materials, packaging, freight and production overhead. These costs have an impact on the price of the materials used in a quality low voltage installation. To make matters worse, residential construction, a savior for many installers, has refused to be the leader it once was.

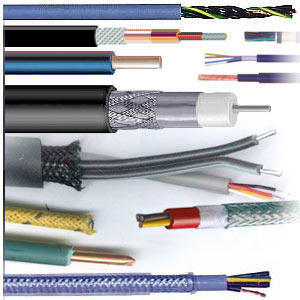

We wire and cable manufacturers have a goal to supply a quality product at a competitive price, but we also have a responsibility to educate our customers on the cable types that will help them reduce costs and improve installation quality.

Here are several tips that may help add to the bottom line of your next sound, video or CCTV job.

Gauge Your Costs

The last few years have seen a huge growth in sound installations. What was once a niche business for integrators has now become a great revenue source for security firms, builders and electrical contractors alike.

Since sound installations come in many shapes and sizes, the size of the cable or gauge continues to be very important. Most equipment manufacturers do a pretty good job of specifying an acceptable line loss and its corresponding gauge size. If you feel it is necessary to bump up the gauge size for future expansion, be aware that a bigger size conductor costs more money and may be unnecessary for the application.

Furthermore, most sound cable conductors are stranded and stranding counts can vary. (It’s worth noting that high-stranded cables may be easier to install through a raceway or conduit.) And let’s face it: saving on installation costs is very important.

If, however, you have an open pathway with limited twists and turns, a small stranded conductor will save you a few dollars on the material side. The higher the stranding, the higher the cable costs. Choose the one that is suitable for the installation and, at the same time, is cost effective.

Put Money in Your Jacket

Innovations in cable jacket design have also had an impact on the price of cable. Pressure extruded jackets fill the niches between the conductors, making a durable product that is quicker to install and easier to pull without breaking.

Extruded jackets also protect the cable from “staple shorts.” Staple shorts can occur when the conductors are crushed against each other during installation. These types of shorts are difficult to locate and repair.

The traditional sound cable construction is made with a “tubed” jacket. These-easy-to strip jackets are extruded loosely around the conductors. They may require a little more care to install but are usually adequate for hazard-free installations.

Remember, a quick trouble-free job can lead to a great costs savings. Extruded jackets with high-flex stranding may cost more, but they bring installation labor savings. Tubed jackets with low stranding are less expensive but are slightly more difficult to install.

Know the Ropes

Coaxial cables for CATV, CCTV and video are some of the most misunderstood products in the magic land of wire and cable.

It’s important to know the pros and cons of the various cabling options. The RG and RG/U numbers designate the size and type of coax. RG6, for example, is a popular in-wall solution for many CATV and satellite installations. Check the manufacturer’s specification to determine the proper shield and conductor type.

Today, the popular options are copper-covered steel or bare copper conductors and dual or quad shield coax. Since high frequencies tend to travel on the outside of the conductor, copper-covered steel conductors are sufficient for many applications. However, solid copper conductors have become popular with recent satellite services.

These new services require the conductor to supply power to the LNB. A copper-covered steel construction has too much resistance for this application. A little investigation before the installation will save a whole lot of trouble later on.

CATV and satellite coaxial cables always employ a 100 percent foil and variable percent braid combination. The foil shield is most often an aluminum-backed Mylar that is wrapped 100 percent. The braids can be aluminum, tinned copper, or silver with 20 percent to 95 percent coverage depending on your specific budget.

Many metro areas have settled on using an RG6—100 percent foil/60 percent aluminum braid/100 percent foil/40 percent aluminum braid quad shield coax standard. However, some rural providers still work with more cost effective dual shield products. A complex shield has a higher cost but better signal support. Before the installation, check with the local provider for the minimum cable requirements.

Be aware of the difference between CCTV and CATV coax. Most CCTV installations require a solid copper conductor with a 95 percent braid or better. Installing the incorrect product will result in a bad signal and void the manufacture’s warranty.

It may be an advantage to install a coax with 100 percent foil shield and a 95 percent tinned copper braid. By doing so, the cable will support not only low frequency CCTV, but also higher frequency CATV and precision video transmissions.

Material escalation is often an intangible that causes prices to rise in a volatile market.

But don’t be limited by a lack of options. Knowing the facts will empower you to make adequate, and even better, substitutions. Take the time to thoroughly investigate your installation application and find a quality, cost-effective solution to keep ahead of the material curve.

Deane Myers is the product/market manager of Coleman Cable Inc., based in Waukegan, Ill |